INSTALLATION EXAMPLES: FARREL SLIDEWAY INFEED - PRE 1960 VINTAGE ROLL GRINDER

COMPUTERIZED CROWNER RETROFIT SYSTEM

The ph oto below shows a pre tilt infeed

1955 vintage Farrel roll grinder before the crowner retrofit. To change

crowns, the operator must position the wheel at center of the roll face, select

and install the correct

change gears for the roll being ground, relieve the weight on the cam using the

lift jack, manually adjust the cam eccentricity, and lower the wheelhead back

onto the cam.

oto below shows a pre tilt infeed

1955 vintage Farrel roll grinder before the crowner retrofit. To change

crowns, the operator must position the wheel at center of the roll face, select

and install the correct

change gears for the roll being ground, relieve the weight on the cam using the

lift jack, manually adjust the cam eccentricity, and lower the wheelhead back

onto the cam.

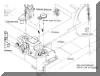

The schematic on the right shows the

modifications required with the RGB crowner retrofit system, and the photos

below show the same machine with these new parts installed. The Servo Cam

Actuator (SCA) utilizes the existing

cam drive train to tilt the wheel in and out. An absolute carriage

position encoder is belt driven from the "drive" change gear shaft. The

new servo motor connects through a harmonic drive reducer and a Ringfeder

keyless friction coupling to rotate the input worm. The cam is preset for

a fixed eccentricity large enough to provide the required infeed amount. A

LVDT provides position feedback of the tilting wheelhead to close the servo

loop. With this arrangement, the operator can set all the crown variables

at the FFG computer station. No manual adjustments are required. A

very important advantage of this design is that the original mechanical crown

drive arrangement remains intact ready to be used as a standby spare if ever

needed.

Actuator (SCA) utilizes the existing

cam drive train to tilt the wheel in and out. An absolute carriage

position encoder is belt driven from the "drive" change gear shaft. The

new servo motor connects through a harmonic drive reducer and a Ringfeder

keyless friction coupling to rotate the input worm. The cam is preset for

a fixed eccentricity large enough to provide the required infeed amount. A

LVDT provides position feedback of the tilting wheelhead to close the servo

loop. With this arrangement, the operator can set all the crown variables

at the FFG computer station. No manual adjustments are required. A

very important advantage of this design is that the original mechanical crown

drive arrangement remains intact ready to be used as a standby spare if ever

needed.