| Home |

ACCURACY CHECKS

COMPUTERIZED CROWNER RETROFIT SYSTEM

In

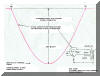

order to obtain a measurement of profile accuracy, an auxiliary LVDT was mounted

independent of the feedback LVDT on the back of the wheelhead (see sketches and

photo below), and the wheelhead pivoting motion recorded on an x-y plotter as

the carriage traversed the roll face. The tests were done on two different

Farrel grinders. The first plot (below left) shows the results for a .010"

concave setting and a 70 degree cosine target shape on an 80" face roll.

Due to the wheelhead pivot ratio, the maximum movement a t the LVDT position at

the back of the wheelhead was about .027". This is the best way to

demonstrate system

t the LVDT position at

the back of the wheelhead was about .027". This is the best way to

demonstrate system accuracy, since the contribution of any bed distortion or

other wheel related

effects are not included.

The resultant plot is a true magnified trace of the actual wheel motion as

controlled by the crowner system. The second check (below right) was done

on another grinder using a similar setup, but with a different crown setting and

on a longer roll face with two different traverse speeds.

accuracy, since the contribution of any bed distortion or

other wheel related

effects are not included.

The resultant plot is a true magnified trace of the actual wheel motion as

controlled by the crowner system. The second check (below right) was done

on another grinder using a similar setup, but with a different crown setting and

on a longer roll face with two different traverse speeds.